Time to begin to realize a return on your investment. Once constructed the commissioning process consists of verification, testing, and sometimes rework.

On your Marks, Get Set,

Time to begin to realize a return on your investment. Once constructed the commissioning process consists of verification, testing, and sometimes rework. Ideally the amount of rework is minimal because testing has taken place during construction. The phrase that “quality is best when designed in” becomes evident when the time for interconnect to the grid finally comes.

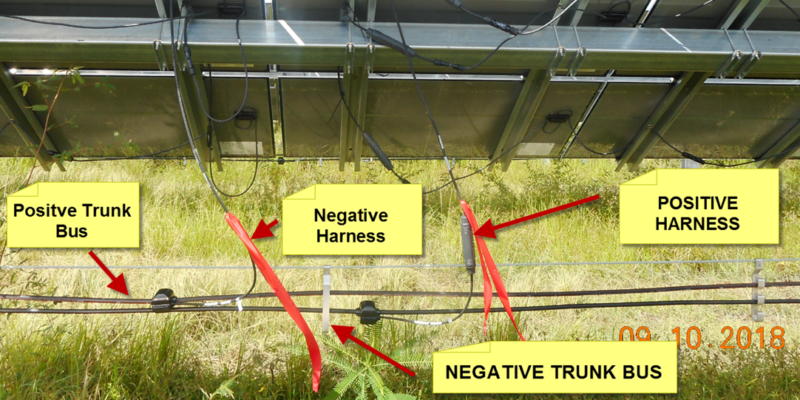

Commissioning verifications and tests vary depending on the system configuration and if any pre-commissioning testing is done. Tests can include looking using thermal imaging to reveal high-resistance connections, amperage tests on tracker motors to test for binding. Some ground faults are not detected by the inverters, requiring specific testing.

Make the Plan, Follow the Plan

Meeting the testing requirements of the various permitting agencies and do so in an efficient manner is itself a dauting task. Retesting, doing the same test to satisfy different agencies can be time consuming, costly, and impact the interconnection commitment. Best practices are to perform as much testing in advance of the final commissioning activities.

Visual inspections during construction that are completed as each string is completed. Mechanical (tracker) testing can be done as each block is completed, and so on. A full list of testing activities, and testing sequences is extensive and can consist of thousands of pages of checklists. Utility solar construction companies have teams dedicated to the commissioning phase.

For the journey leading up to commission, we invite you to our blogs on Preliminary Design through Construction at: https://rrccompanies.com/from-concept-to-reality-advancing-your-solar-utility-project/