Imagine cutting your materials costs by 40%. With the Braced Tube Foundation, this can be a reality for your wind project.

Material costs are one of the biggest concerns for our clients – developers, owners, and EPC contractors. With this innovative proprietary design, we fulfilled the industry’s need for a cost-effective foundation solution.

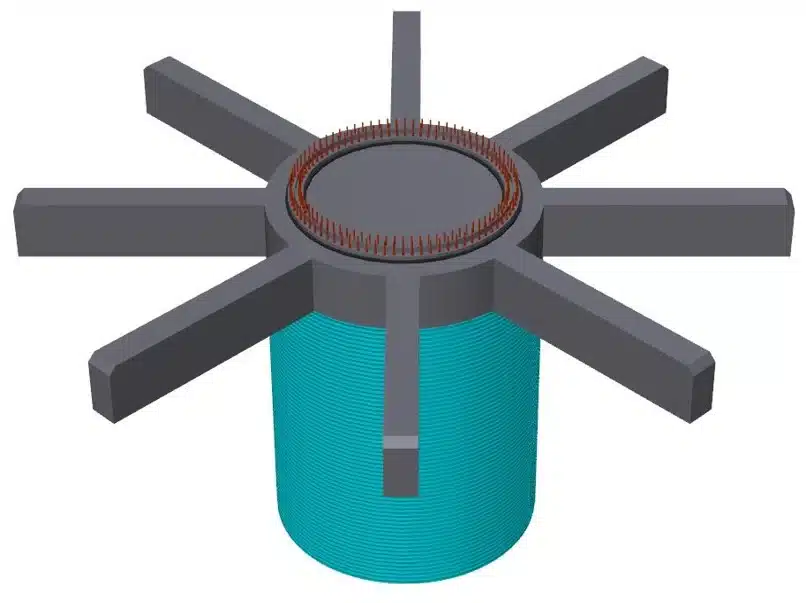

The Braced Tube design builds on a monopile concept. By adding bracing beams on the top, we achieved higher lateral resistance, increased soil stability, and streamlined field verification methods.

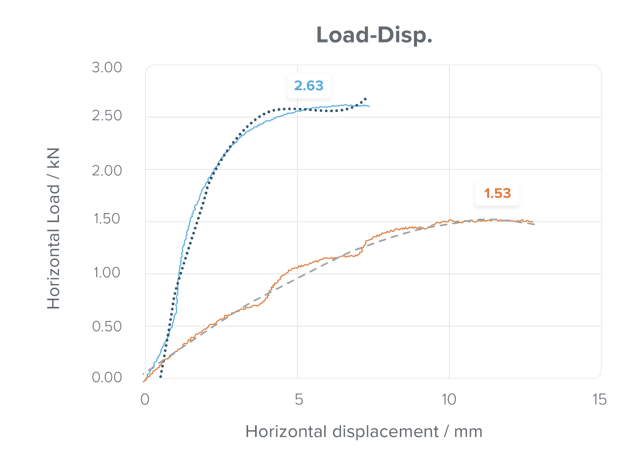

The Braced Tube Foundation exceeded the load capacity of the equivalent monopile foundation by 72%.

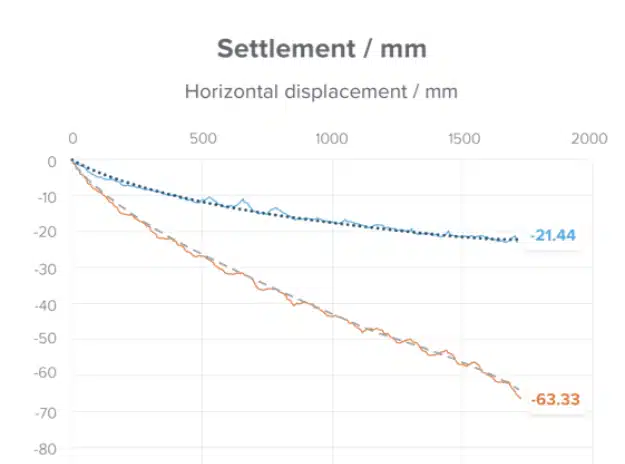

The Braced Tube Foundation had 66% less vertical settlement than the monopile foundation.

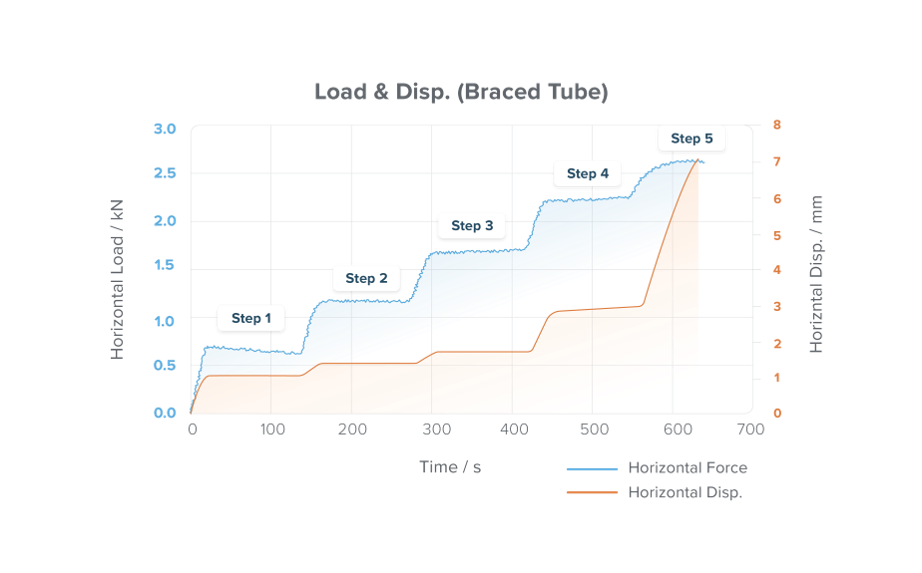

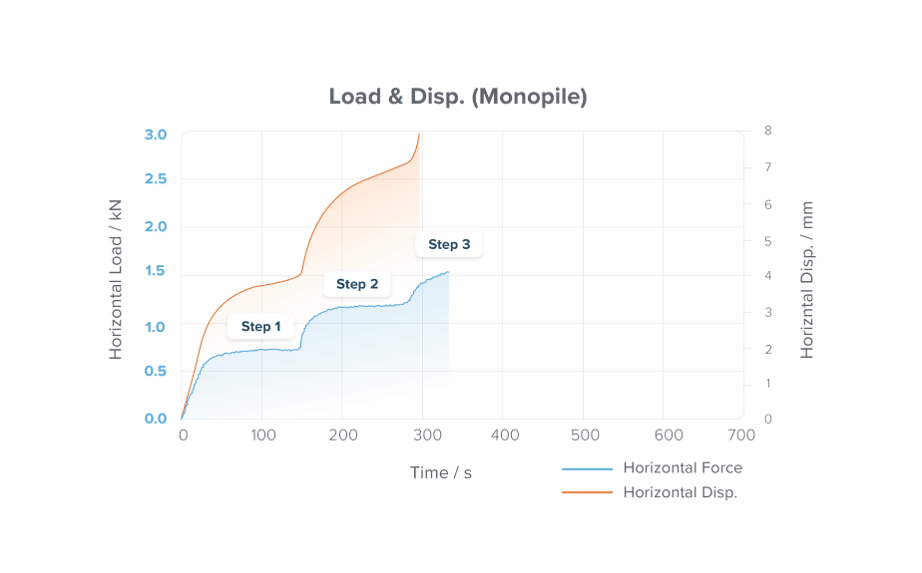

The Braced Tube Foundation reached the 5th step prior to soil failure, with a maximum horizontal displacement of approximately 7 mm.

The monopile foundation failed at the 3rd loading step (loads increased by 0.5 kN each step) with a horizontal displacement of over 13 mm.